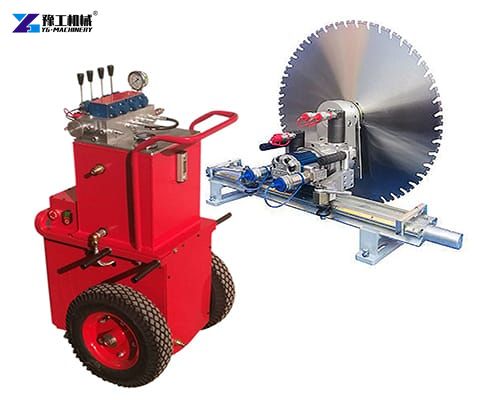

Hydraulic wall saw is a highly efficient cutting engineering equipment, mainly used for precise cutting of building materials, especially for concrete, reinforced concrete, rock, brick walls, ceramics, and other materials. It is widely used in building demolition, reconstruction, and deep foundation pit construction. The concrete wall saw is mainly composed of two parts: the hydraulic power station and the hydraulic saw head. The hydraulic power station provides power for the saw head. The two parts are connected by hydraulic oil pipes, and the saw blade is driven by a powerful hydraulic system. This design makes the concrete wall saw more flexible and efficient in operation. Its advantages are high cutting accuracy, low noise, and low vibration, which is suitable for small space operations. It is easy to operate and maintain as an important tool in construction, which can greatly improve work efficiency and safety.

Main Features

- High efficiency: This wall saw machine uses the hydraulic system to provide powerful power, which can easily cut concrete with a thickness of tens of centimeters, greatly improving the cutting efficiency and shortening the construction period.

- Precise cutting: With professional cutting blades, the concrete wall saw can achieve precise straight-line cutting, the direction of movement is controlled by the track. The cutting position is accurate, the error in the traditional cutting method is avoided, and the cutting surface is smooth and neat.

- Strong adaptability: It is suitable for cutting a variety of hard building materials, including reinforced concrete, rocks, walls, floors, etc.

- High safety: The concerte wall saw has multiple safety designs, overload protection functions, and safe and reliable operation.

Main Applicable Fields of Hydraulic Wall Saw

- Construction project renovation: concrete wall saw machine is originally designed for cutting concrete walls. They are widely used for opening doors, windows, vents, and other operations on walls, as well as for cutting reinforced concrete beams and columns. It is convenient for construction workers to open holes, demolish and renovate.

- Bridge and floor cutting: In bridge construction and maintenance,it is often used to cut supporting beams, concrete piers, bridge decks, and other structures. At the same time, it is also suitable for floor cutting, maintenance, and renovation.

- Tunnel construction: It is used to cut the concrete structure inside the tunnel to facilitate tunnel construction and maintenance.

- Stone processing: Due to its powerful cutting ability and precise cutting effect, concrete wall saws are also used in the stone processing industry to meet various stone-cutting needs.

- Water conservancy projects: It is used to cut the concrete structures of water conservancy facilities such as dams and levees for maintenance and renovation.

Precautions for Use

1. Before using the equipment, ensure that the equipment is in good working condition and check whether the components of the wall saw machine are in good condition, including the oil quantity and quality check of the hydraulic oil, as well as the condition and installation position check of the blade.

2. When using the concrete wall saw machine, it should be carried out in strict accordance with the operating procedures, to ensure that the working area has sufficient ventilation and lighting, and pay attention to safety and stability.

3. When operating the it, wear personal protective equipment, including safety helmets, goggles, gloves, etc.

4. When using the hydraulic wall saw, operate it according to the requirements in the operating instructions, and do not arbitrarily change the settings or parameters of the equipment.

5. When the equipment is working, it is necessary to check the operating status of the equipment regularly to ensure that the equipment works normally and discover and deal with the fault in time.

6. After using the wall cutting saw, the equipment should be cleaned and maintained to keep the equipment in good condition and extend the service life of the equipment.