An anchor drilling machine also known as a bolt drilling rig is a kind of pneumatic impact machine. The anchor drilling rig is mainly used in the anchoring of landslides and dangerous rock masses in the prevention of various geological disasters. It is suitable for the construction of urban deep foundation pit support, anti-floating anchors, foundation grouting reinforcement engineering holes, and blasting holes for blasting engineering. High-pressure jet grouting piles, tunnel pipe shed support holes, and the powerhead can be slightly changed to facilitate all-around construction. The rock anchor drilling rig has been applied widely, and its excellent performance has been recognized by the majority of construction units. Contact us to get more information by clicking the button and filling in the table for the quote.

Parameters of Anchor Drilling Machine

| Model | YG-MDL80 | YG-MDL150 | YG-MDL200 |

| Hole diameter(mm) | 100-210 | 150-250 | 150-250 |

| Hole depth(m) | 60-100 | 130-170 | 180-220 |

| Rod diameter(mm) | 73/89/102/114 | 73/89/102/114 | 73/89/102/114 |

| Hole angle(°) | -10-90 | 0-90 | 0-90 |

| Output rotary speed(r/min) | 16-105 | 10-170 | 40-170 |

| Powerhead output torque(N.m) | 4200 | 7500 | 11000 |

| Stroke of slide frame(mm) | 1800 | 3400 | 3400 |

| Lifting force of powerhead(KN) | 65 | 70 | 80 |

| Feeding force of powerhead(KN) | 33 | 36 | 40 |

| Moving speed(km/h) | 15 | 20 | 22 |

| Input power(kW) | 39 | 96 | 96 |

| Dimension(mm) | 3000×1800×1500 | 5400×2100×2000 | 6200×2100×2000 |

| Weight(kg) | 3200 | 6500 | 9200 |

Anchor Drilling Rig for Sale

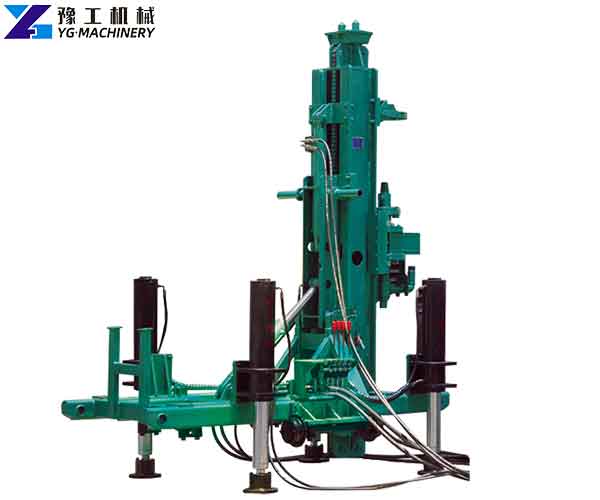

The main boom of the anchoring rig can be pitched in the range of 90°, and the drill frame can be swung in the range of 180°. This unique design of the telescopic and rotating boom enables the rig to perform multi-layer anchoring operations within a height of 6 meters. Its mainframe can rotate 360°, and intensive drilling operations can be realized within a certain range. The anchor drilling machine has high drilling efficiency and moderate fuel consumption, which greatly improves the adaptability and operating efficiency of the rig, greatly reduces operating costs, and truly maximizes benefits. It can reach the deepest drilling depth of 120 meters and the fastest drilling speed of 1 meter per second, with the advantage that the main boom can be automatically extended and the machine head can be rotated 360 degrees. It is suitable for working under high drilling density and adapting to geology.

Anchor Drilling Machine Classification

- Full hydraulic anchor drilling rig

The rotary power, propulsion power, and auxiliary actions of this type of drilling rig are all driven by hydraulic pressure, and the hydraulic station is driven by an electric motor or an internal combustion engine. This type of drilling rig has a wide adjustment range, a larger applicable aperture and depth, better hole-opening and anti-jamming capabilities, and flexible and convenient operation.

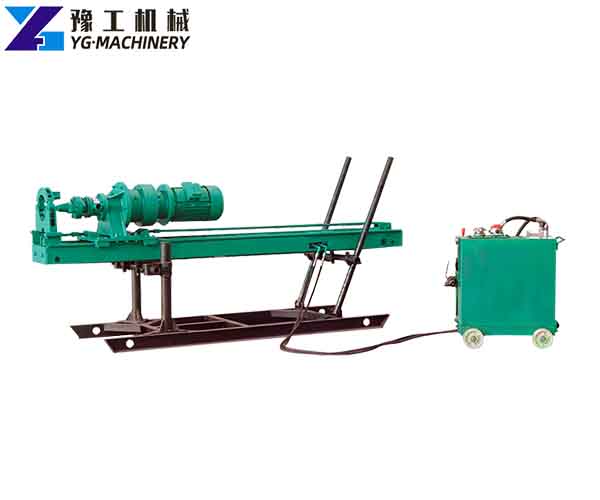

- Electric-hydraulic anchor drilling machine

The rotation of this type of drilling rig is powered by a motor, and the propulsion and auxiliary actions are powered by hydraulic pressure. Most of the anchor drilling rigs currently in use are fully hydraulically operated with internal combustion as the power. Equipped with hydraulic rock drills, they have a single power, and a large processing range, suitable for soil and rock anchors, but they have great advantages in soil anchors.

What Factors Affect the Work Efficiency of Anchor Drilling Rigs?

- Choose the diameter of the drill bit and the length of the drill rod.

- Equipment maintenance is not in place, and effective maintenance can increase the service life and accuracy, and the efficiency of the anchor drilling rig is reduced because of the lack of frequent maintenance.

- The discharge of drill cuttings, the size of the wind pressure, the choice of cooling medium, etc. can anchor the drilling rig and the drilling efficiency of the bolter.

- The choice of speed depends on the choice of rock formation. For example, for some hard rock formations, the speed and feed speed of rubbing the bottom is more appropriate, and a higher speed will backfire.

- Of course, the wrong operation also has a certain impact on efficiency. The bolt drill must drill at a powerful angle when impacting the rotary drilling.

Features of Crawler Anchor Drilling Machine

- The drilling rig adopts an open body, which is easy to maintain and maintain; It is quick and accurate to adjust the hole, the auxiliary time for adjusting the angle is short, the whole angle is accurate, and the labor intensity is low.

- Fully hydraulic drive, convenient and flexible operation, convenient displacement, good maneuverability, and can be applied to work on high slopes and scaffolding.

- The rock anchor drilling machine integrates the operation of the console panel and the drilling rig crawler with mobile functions. It has the characteristics of convenient operation and reasonable layout, giving the operator good and comprehensive protection and visibility.

- The gyrator is driven by dual hydraulic motors, and the output torque is large, which greatly improves the smoothness of the drilling rig.

- Adopt a full hydraulic system, with a good heat dissipation effect, is safe and reliable.

- Feeding through a large oil cylinder, with strong drawing force and feed force, plus its long stroke, can effectively improve drilling efficiency.

- The drilling rig is suitable for a variety of drilling processes. The output speed of the powerhead is continuously variable. The drilling parameters can be independently selected according to different construction requirements and geological conditions to achieve the best drilling efficiency.

- The drilling rig is composed of three parts: the main engine, hydraulic station, and operation platform. It has good detachability and is easy to transfer; the mast of the main engine can be directly connected with the hydraulic station, which has a simple structure; the hydraulic station frame is equipped with rollers for easy movement and relocation.

Related Products

In addition to the anchor drill rig, YG Machinery also has other drill equipment. We have a rotary drilling machine for sale, an auger drilling rig. small water well drilling rigs for sale. core drilling rig, DTH drilling rig. And there are other types machines, such as sandblasting machines, shot blasting machines, cement mortar spraying machines, pile breakers, concrete pumps for sale. fog cannon for sale, electric pipe bender machines, and so on. If you want to buy construction machinery, please feel free to contact us. Email: admin@ygbuildingpro.com. Whatsapp/Phone/Wechat: +86 18337123872