The disposable paper cup making machine is applied to produce paper containers by mechanically processing the base paper, which is made of chemical wood pulp. The final product has a cup-shaped appearance and can be used for frozen food and hot drinks, as disposable paper cups for water, juice, cola, coffee, milk tea, cold drink, ice cream, instant noodles, popcorn, cake, etc. Disposable paper cups have the characteristics of safety and health, are lightweight and convenient, and are often used in restaurants, coffee shops, convenience stores, beverage stores, and other public places. Our company has lots types of automatic paper cup making machines for various specifications to form paper cups. If you plan to invest in the paper cup production business, please get in touch with us, and we will send more details to you. Email: admin@ygbuildingpro.com 【Phone/Whatsapp/Wechat】: +86 18337123872

Automatic Paper Cup Making Machine for Sale

Paper cups are divided into single-sided PE-coated paper cups and double-sided PE-coated paper cups. As the name implies, single-sided PE-coated paper cups are paper cups produced with single-sided PE-coated paper. Most of the common market paper cups and advertising paper cups are single-sided PE-coated type paper cups, and the water-filled side has a smooth PE-coated film. Double-sided PE-coated paper cups are paper cups made of double-sided PE-coated paper. The inner and outer sides of the paper cups both have PE-coated films and are mostly used for cold drink cups. From this point of view, here are single and double side PE-coated disposable paper cup making machines for sale in YG Machinery.

Paper Cup Making Machine Parameter

| Model | YG-DP09 | YG-DP16 | YG-GS120 | YG-160S | YG-M100 |

| Production speed | 80-110pcs/min | 70-90pcs/min | 100-120pcs/min | 130-160pcs/min | 80-100pcs/min |

| Voltage | 380V/50hz three phase | 380V/50hz | 380V/50hz three phase | 380V 3-phase electricity | 380V(220V) 50hz |

| Paper cup specification | 3-12 oz | 3-16 oz | 3-16 oz | 5-16 oz | 3-16 oz |

| Machine size | 2150*1100*1750mm | 2150*1100*1950mm | 2180*1050*1600mm | 2800*1100*1800mm | 2000*1110*1850mm 1400kg |

| Paper stock | 160-350g single PE coated paper | 160-350g single PE-coated paper | Single and double-coated paper | Single/double PE/PLA coated paper | One side, or two side PE coated paper(single PE or double PE coated paper |

| Power | 7.8kw | 5.5kw | 7kw | 25kw | 4.5kw |

| Weight | 1700kg | 1600kg | 2100kg | 4000kg | 1500kg |

Features of Disposable Paper Cup Making Machine

-

Reliability:

The cup forming machine has the advantages of high performance, high benefits, and high quality. The integral steel plate body and the oil-sprayed lubrication system ensure the long-term normal and stable operation of the equipment

-

Energy efficient:

Advanced high-precision cylindrical cam drive combined with gear transmission makes each station form accurately. Servo tracking feeds the bottom paper to lock the size of the cup bottom paper, effectively saving raw materials.

-

Advanced technology:

The bottom of the cup adopts 2 flameless heating;

Photoelectric detect and report each link in the production

-

Humanization:

The human-machine interface PLC system controls the stable operation of the whole machine for a long time. The reasonable setting for automatic counting and cup collection table coordination can replace the busy manual work.

-

Bonding process:

The disposable paper cup making machine has a heating station to heat the PE film on the surface of the PE-coated paper and compact it through the side and bowl bottom pressing mechanism. After cooling, the paper cup production machine can achieve a firm bonding effect.

-

High performance:

The equipment has an excellent steel frame, simple operation panel, stable drive system, security alarm system, professional humanized design, simple operation and convenient maintenance, and high quality and low consumption.

Paper Cup Forming Production Process

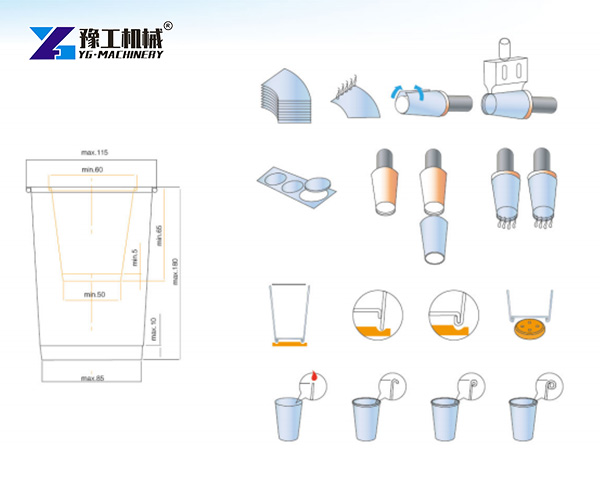

The automatic disposable paper cup machine can produce paper cups through automatic film feeding, sealing, oil dipping, bottom cutting, bottom curling, roll sealing, crimping, cup unloading, and other functions. The equipment has the advantages of high efficiency, power saving, practicality, etc. It is an ideal paper cup forming machine for producing paper beverage cups and food packaging products. The forming material of the paper cup machine is generally divided into single PE-coated paper and double PE-coated paper. Different materials may have some impact on the configuration of ordinary paper cup machines, but medium and high-end models will not. Place the semi-finished fan-shaped paper on the working station, then the equipment will finish the production process. Different types of paper cup production machines have different manufacturing size ranges, speeds, production output, etc.

Safe Consideration Setting Designs of the Cup Forming Machine

- Automatic alarm for too little paper

- Multiple sheets of paper detection stop

- Automatically track the paper and feed the bottom paper

- Ultrasonic probe detection stop

- Servo conveying without cup bottom detection stop

- It does not work when the bottom molding does not reach the set temperature

- The heater will automatically drop when the detection stops and does not work

- The whole machine adopts an automatic detection function

Paper Cup Making Machine Manufacturer – YG Machinery

The disposable paper cup making machine is a valuable investment. In recent years, more and more countries have promoted green environmental protection materials. The paper cup is a trend instead of the plastic cup. YG Machinery provides lots of paper cup production machines for different specifications and usages. Besides, we also supply tissue-making machines, food and non-food packaging machines, wet wipes-making machines, and so on. Welcome to contact us to get a free quote. Email: admin@ygbuildingpro.com 【Phone/Whatsapp/Wechat】: +86 18337123872