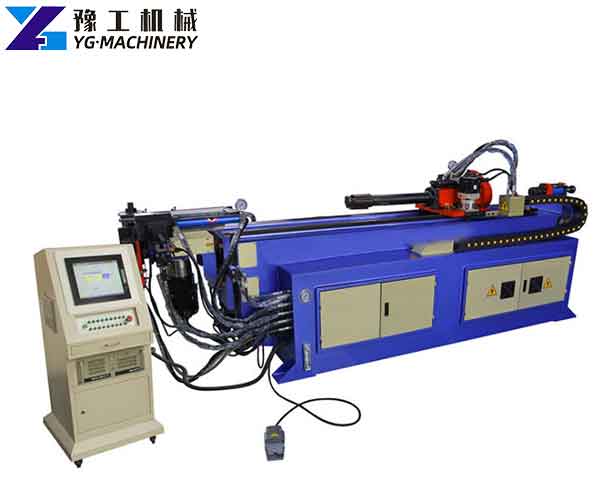

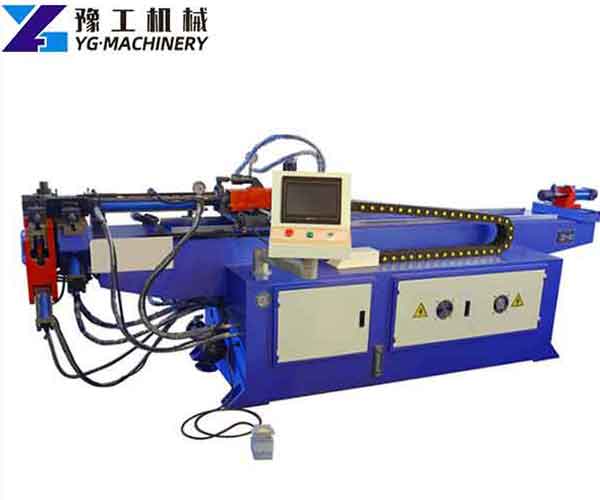

An electric tube bender is an electric tool that bends a metal pipe to a certain angle or arc. It has the advantages of electric pipe bending function, lifting function, multiple functions, reasonable structure, simple operation, convenient movement, and fast installation. An electric tube bender machine is mainly used for electric power construction, boilers, bridges, ships, furniture, highway and railway construction, decoration engineering, hardware products, etc. In addition, there are pipe rust removal machines, pipe shrinking machines for sale.

Pipe Bending Machine for Sale

Pipe bending machines can be divided into electric pipe bender machines, hydraulic pipe bender machines, automatic pipe benders, etc. They are widely used in electric power construction, highway and railway construction, bridges, ships, etc. An electric pipe bender machine is an electric tool to bend a metal pipe in a certain angle or arc. It has the advantages of pipe bending function, lifting function, multiple functions, reasonable structure, simple operation, convenient movement, and fast installation.

Parameter of Electric Tube Bender

| Model | YG-WG28 | YG-WG38 | YG-WG51 | YG-WG76 | YG-WG100 | YG-WG150 |

| Type | Electric Type/Hydraulic Type | Hydraulic Type | Hydraulic Type | |||

| Bending angle | 0-180° | |||||

| Apply for diameter of steel pipe | 10-26mm | 16-38mm | 16-51mm | 16-76mm | 25-100mm | 25-133mm |

| Power/voltage | 2.2kw/380v | 3kw/380v | 3kw/380v | 4kw/380v | 7.5kw/380v | 11kw/380v |

| Main shaft rotary speed | 20r/min | 16r/min | 8r/min | 8r/min | 9r/min | 9r/min |

| Bending angle quantity | 10 | 10 | 10 | 10 | 9 | 9 |

| Applicable pipe thickness | ≤2mm | ≤3mm | ≤3mm | ≤3mm | ≤3mm | ≤5mm |

| Machine size | 80*65*90cm | 90*80*100cm | 90*80*100cm | 100*90*110cm | 180*200*135cm | 190*210*140cm |

| Machine weight | 180kg | 260kg | 300kg | 350kg | 1200kg | 1500kg |

| Remark:

Electric type means semi-automatic, Hydraulic type means full automatic (Mainly difference in working efficiency) |

||||||

How Does An Electric Tube Bender Work?

The electric pipe bender machine is composed of electric oil pump, high pressure oil pipe, quick coupling, working oil cylinder, plunger, elbow parts including mold, roller shaft, etc. The electric tube bender starts the oil pump by the electric motor and then drives the bending cylinder to run, and then the main output shaft is driven by the rack to drive the bending work device to rotate to the specified position set by the CNC program, which generates a large thrust. Here, the tube can be bent by the bending part. . The motor automatically reverses. When the bending work device returns to the stop position, the CNC program cuts off the circuit and the motor stops working.

Features of Electric Tubing Bender:

- The electric pipe and tube bender mainly adopts full touch screen mode, which is more advanced and brings great convenience to people. The program setting is very simple and it is easy to use.

- The bed structure is stable and not easy to deform.

- Each file can set 16 bending angles, and the memory can store 16 sets of files.

- With slow positioning function, the bending angle is stable, and the repeatability is up to ±0.1°

- Screen automatic information error display: When there is an error message, there will be an information prompt on the screen of the automatic pipe bender, so that the worker can find the error and deal with it in time.

- Provide self-developed coordinate conversion elbow processing values. The software can be installed on the desktop computer to edit and calculate.

An Important Part of Electric Tube Bender:

- The rocker arm, its function is to ensure that the bending radius of the elbow meets the requirements, and its clamping seat is to limit the rebound of the steel pipe during the bending process.

- The pumping station is divided into high pressure and low pressure ports to provide power for the opening and closing of the guide roller, the rocker arm clamping seat cylinder, the opening and closing of the trolley chuck of the pushing device, and the opening and closing of the straightening roller.

- The guide roller device is composed of two sets of guide rollers, a frame, and a clamping transmission system. The opening and closing of the guide roller are completed by hydraulic drive, and its function is to complete the horizontal bending of the steel pipe together with the rocker arm.

- The driving device is the power source of the pushing device.

- The straightening roller is to prevent vertical deformation during the bending process and is used in conjunction with the floating anti-ellipse fixture to ensure that the ellipticity of the steel pipe after bending meets the requirements.

- The pushing device (consisting of the trolley, bed, drive shaft, traction chain, etc.) pushes the steel pipe forward, and the steel pipe is bent under the action of the rocker arm and the guide roller.

Electric Tube Bender Machine Manufacturers

With the development of industry, the shape requirements for many metal pipes are constantly changing, and ordinary pipe benders can no longer meet the demand. A fully automatic pipe bender machine uses LCD touch screens and menu-based operations, which are easy to learn and understand. And program setting is easier. The automatic pipe bender machine has its own detection and error message display, which can easily eliminate operating errors and malfunctions and improve the quality of the product. In addition, there are pipe shrinking machines, rebar derusting machines, electric pipe bender machines. Contact us to get an electric tube bender price right now.

Other Products

YG Machinery is a manufacturer of construction machinery, YG Machinery owns a variety of machinery and equipment. For example, pile breaker machine, small water well drilling machine, fog cannon dust suppression, cement sprayer machine, mobile concrete pump, anchor drilling machine, sandblasting equipment for sale, etc. Contact us now.