The floor shot blaster is a machine for roughening the road surface, and rust removal of steel. It is used to remove the slurry and impurities on the surface of concrete and asphalt, roughen the concrete surface, and improve the roughness, adhesion, and anti-skid performance of the road surface. Moreover, the device greatly improves the adhesion strength between the waterproof layer and the concrete base. It is widely used in concrete waterproof line roughening treatment, tunnel maintenance, preventive maintenance of airport runways, municipal roads and paved roads, small area steel surface cleaning, and other fields.

Technical Parameters of Floor Shot Blaster

| Model |

YGFY-270 |

YGFY-550 |

YGFY-850 |

| Work Width |

270mm |

550mm |

850mm |

| Diameter of shot blast wheel |

200mm |

||

| Work efficiency on concrete surface |

150㎡/h |

600㎡/h |

600㎡/h |

| Work efficiency on steel plate surface |

50㎡/h |

80㎡/h |

100-160㎡/h |

| Shot blaster motor power |

11kw |

2*11kw |

2*15kw |

| Supporting dust collector |

Six-core automatic backflush vacuum cleaner |

Eight-core automatic backflush vacuum cleaner |

Twelve-core automatic backflush vacuum cleaner |

| Walking speed |

0-30m/min |

5-25m/min |

5-25m/min |

| Walking motor |

0.75kw |

0.75kw |

1.5kw |

| Suggest the diameter of the steel shot |

1.2-1.8mm |

1.5-1.8mm |

1.5-1.8mm |

| Dimension |

1*0.3*1.1m |

2.05*0.72*1.46m |

1.95*1.02*1.55m |

| Weight |

150kg |

595kg |

700kg |

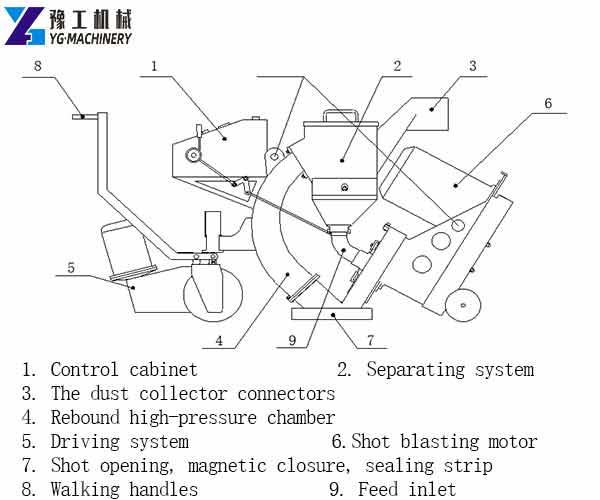

Floor Shot Blasting Machine Composition

The floor shot blaster is mainly composed of a shot blasting motor, an electric control box, a traveling motor, an orientation sleeve, a shot blasting wheel, and a storage and feeding hopper. The dust collector is composed of a fan, an air compressor, a filter system, and a dust storage system.

Working Principle of Floor Shot Blasting Equipment

The working principle of the floor shot blaster is to throw the shot onto the working surface at a high speed and a certain angle by mechanical means, so that the shot hits the working surface, roughens the surface of the road, and removes residues. Then, through the airflow cleaning function of the matching vacuum cleaner inside the machine, the pellets and the cleaned impurities are recovered separately, and the pellets can be reused. The machine is equipped with a dust collector to achieve dust-free and pollution-free construction, which not only improves efficiency but also protects the environment.

Working Conditions of the Floor Shot Blasting Machine

1. Temperature: -20°C ~ 60°C; the surface temperature of the steel plate is 3°C above the dew point

2. Humidity:

a. When the steel surface is shot blasted, the relative humidity is not more than 90%

b. The relative humidity of concrete shot blasting should not exceed 95%

3. Altitude: 0~3000m

4. Do not operate in rainy or snowy weather

Frequently Asked Questions (FAQ) about Floot Shot Blaster

- What is the requirement for the working plane of the floor shot blaster?

Working surface unevenness <10mm; no water and relatively dry; slope <25° - What is the material of the inner lining of the shot blasting machine?

High Strength Wear Plate - How many square meters can the 270-floor shot blasting machine throw in one day?

Concrete is about 150 square meters, and steel plate is about 50 square meters - Can the floor shot blaster adjust the depth?

The speed can be adjusted, according to the depth of grinding, the slower the walking speed is, the deeper it is, the faster it is, the shallower it is.

Floor Shot Blaster Manufacturer – YG Machinery

You can tell us your project situation, such as cleaning width, work efficiency, budget, etc. The engineers and sales managers of YG Machinery will recommend the floor shot blaster that meets your needs. In addition, we also sell industrial shot blasting machines, asphalt crack fillers, road marking machines, floor grinding machines, and other equipment. Therefore, no matter what kind of road equipment you need, you can contact us, and YG Machinery can provide you with professional advice and equipment to meet your needs.