The PET bottle blow molding machine applies to any shape of the plastic container and plastic bottle. It has a wide application, mainly including carbonated beverage bottles, mineral water bottles, baby bottles, oil bottles, petroleum bottles, cosmetic bottles, pesticide bottles, medical bottles, space cups, lampshades, and so on. There are different bottle production solutions for different bottle volumes and outputs. Semi-automatic or fully automatic, one cavity, two cavities, four cavities, and six cavities are optional. People can choose the suitable one according to the actual demands. Besides, we have professional teams for customizing the model of the bottle that you want to produce. So you do not need to worry about it. If you are going to purchase a plastic water making machine, please get in touch with us to get more details. Phone/Whatsapp/Wechat: +86 18337123872 Email: admin@ygbuildingpro.com

Parameters of Automatic Plastic Bottle Molding Machine

| Parameter | Model | YG-A2 | YG-A4 | YG-A6 |

| Product specification | Max. Container volume | 0.25L, 1.5L | 0.3-1L | 1L |

| Cavity number | 2 pcs | 4 pcs | 6 pcs | |

| Max. Container diameter | 90mm | 100mm | ||

| Max. Container height | 330mm | 350mm | ||

| Max thread size | 40mm | 38mm | ||

| Theoretical yield | 1600-1800 bottles/hour | 3000-4500 bottles/hour | 9000 bottles/hour | |

| Machine specification | The opening stroke | 125mm | ||

| Mold thickness | 180mm | 200mm | ||

| Mold center distance | 75mm | 114.3mm | ||

| Total power | 56kw | |||

| The actual use of power | 15-20kw | |||

| Appearance size | 4.3*1.7*2.2m | |||

| Weight | 3800kg | |||

| Machine size | Appearance size | 2.1*1.3*2.5m | ||

| Weight | 255kg | |||

How to Operate the Plastic Water Bottle Making Machine?

Step 1. Place the preform in the preform container, and automatically enter the preform positioning device through the conveying device.

Step 2. Automatically load the preform with the preform mouth up on the preform holder, and then send it into the heating tunnel.

Step 3. After heating, the preform is sent to the blowing platform, and then the mold is locked, followed by high and low-pressure blowing, exhaust, and finally the mold is opened.

Step 4. Take off the finished bottles from the PET bottle blow molding machine manually or by an automatic mechanical device.

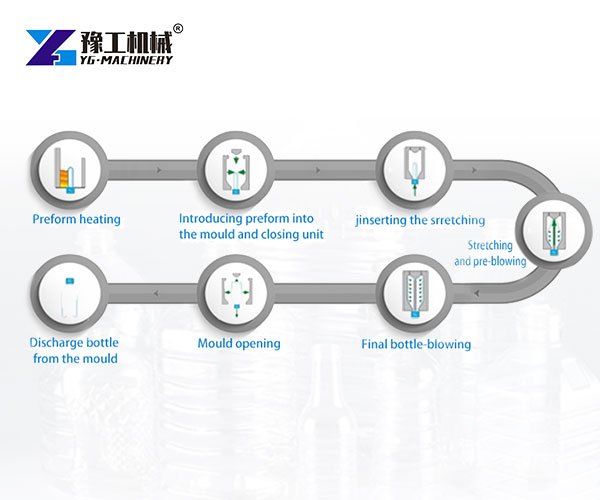

Preheating and Blowing Working Process of the PET Bottle Blow Molding Machine

-

Preheating the preform

Irradiate the preform (bottle embryo) with an infrared high-temperature lamp tube to heat and soften the body part of the preform. It requires a certain cooling device to cool it. In order to maintain the shape of the bottle mouth, the mouth of the preform does not need to be heated.

-

Blowing bottles in molds

In this stage, place the preheated preform (embryo) into the blow mold, and inflate its inside with high pressure so as to blow the preform into the required bottles. PET bottle blow molding machine on the market is generally divided into two types: fully automatic and semi-automatic. The automatic type can put the preheated preform into the blow mold or take off from the mold automatically instead of manually operating. The production rate is greatly improved, and of course, the price is higher than that of semi-automatic ones.

How to Choose A PET Bottle Blow Molding Machine?

We can select the water bottle making machine from the bottle volume, output, and budget. For different bottle volumes, the bottle output may be different. Generally, the smaller the bottle volume, the bottle output is more. For 500ml bottles, if the output is not more than 1500 bottles per hour, the semi-automatic types can meet the needs. If it is more than 2000 bottles per hour, it is better to use fully automatic types. Besides, the water bottle blowing machine price is an inevitable factor to be considered. Choose the suitable one based on the budget. Generally speaking, choose the model of the PET bottle blow molding machine according to the products you need, and generally pay attention to the number of cavities, the size of the bottle capacity, and the output per hour. It is very important to choose the model that meets your needs through your own needs.

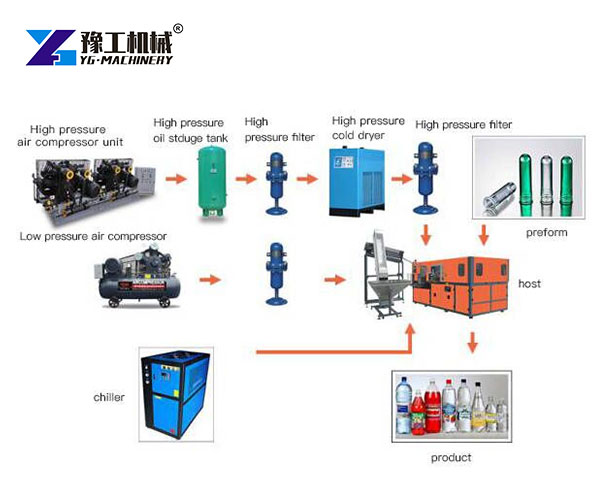

Auxiliary Devices for Blowing Plastic Bottles with Good Appearance

Air compressor:

The PET bottle blow molding machine has many actions that require an air source, and the air compressor produces a high and low-pressure air source as a power. High-pressure gas only blows the bottle, even in the process of blowing up the embryo. The higher the configuration of the PET bottle-making machine, the fewer places to use the air source as power, and the higher the configuration, the more use the servo.

The chiller:

The cold dryer is to dry the moisture in the air. And the bottle blown out by the dried high-pressure gas is more transparent. It is clear that there is no water ripple when blowing out. And the appearance of the blown-out bottle is better.

PET Bottle Blow Molding Machine Manufacturer & Supplier

Henan YuGong Machinery Co., Ltd is a company that has been engaged in machine manufacturing and supplying for over 18 years. Our PET bottle blowing machine has received much good feedback from our customers. We provide various equipment, such as water bottle molding machines, paper bowler production machines, disposable paper cup making machines, automatic packaging machines, water bottle filling machines, wet wipes making machines, tissue making machines, construction machines, drilling equipment, steel processing machines, etc. If you are looking for these machines, get in touch with us and we will provide more details for you. Email: admin@ygbuildingpro.com Phone/Whatsapp/Wechat: +86 18337123872