The pipe shrinking machine is to shrink one end of the pipe through hydraulic pressure. The steel pipe shrinking machine is usually used for the reuse of waste steel pipes at construction sites, connecting long steel pipes and shortening joints. The steel pipe shrinking equipment has different models according to the diameters of the pipes, and the hot sale types mainly include two types, YG-48 type, and YG-58 type. They are suitable for different diameters of the tubes commonly in the markets. If the size you want to process is not in the two types, we also provide customization services to meet the special requirements. The equipment is simple to operate, easy to use, and has a wide range of applications. And it has received a lot of praise from our customers. Contact us and we will reply to you within 24 hours. Email: admin@ygbuildingpro.com, Phone/Whatsapp/Wechat: +86 18337123872

YG-48 & YG-58 Pipe Shrinking Equipment Technical Parameters

|

Model |

YG-48 | YG-58 |

|

Steel pipe diameter |

48-57mm |

48-60mm |

|

Power |

220V,380V, 4kw optional |

5.5kw |

|

Shrinkage of diameter |

25mm |

30mm |

|

System pressure |

31.5Mpa |

35Mpa |

|

Weight |

240kg |

320kg |

|

Dimension |

700*450*1050mm |

800*500*1100mm |

Parameters of Hydraulic Pipe Shrinking Machine

| Product Name | Hydraulic Pipe Shrinking Machine |

| Model | Hydraulic-3 cylinder |

| Pipe Diameter | 20-60mm |

| End Straight | Max.120mm |

| Pipe Thickness | 1.5-3mm |

| Motor | 3kw |

| Voltage | 380V,50Hz,3 phase |

| Working Speed | 3000-5000pieces/day |

| Weight | 600 kg |

| Packing Size | 1800*700*1800mm |

Working Principle of Steel Tube Shrinking Machine

Through mechanical transmission, the steel pipe is driven to rotate, and one end of the steel pipe is heated by flame. When the pipe shrinking tool reaches a certain temperature, a forming die drives the heated steel pipe head until it becomes the required shape. The steel tube shrinking machine can realize shrinking, taking over, and connecting. Designed and manufactured using hydraulic component technology, it has the advantages of small size, lightweight, compact structure, simple operation, advanced oil circuit design, high efficiency, and reliable performance.

Where is the Steel Tube Shrinking Equipment Mainly Used?

The pipe shrinking machine is mainly used in construction sites. Iron pipes, square pipes, round pipes, galvanized pipes, and stainless steel pipes for reducing diameter and neck expansion are ideal pipe end-forming equipment. The steel tube shrinking machine is suitable for all kinds of mechanical high and low-pressure oil pipes, air pipes, water pipes, cable joints, automobile air conditioning pipes, automobile power steering pipes, engine oil pipes, gasoline oil supply pipes, as well as construction accessories, daily hot water pipes. Used in industries such as vehicles, engineering machinery, hydraulic machinery, welding, and cutting equipment. The specifications of the shrinking machine required by different projects are different.

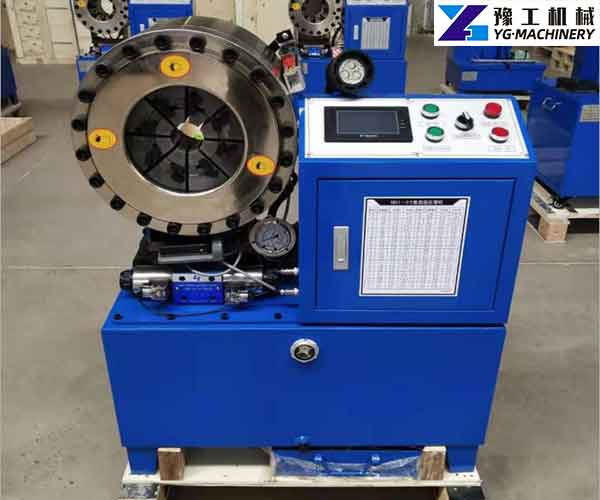

Features of Hydraulic Pipe Size Shrink Machine

- Lots of control types are optional, such as microcomputer control, hydraulic drive, manual, semi-automatic, and fully automatic operation modes, and so on. The footswitch has multiple functions start and emergency stop.

- It adopts a single station, double station, three stations, and multiple stations. The steel tube shrinking machine can shrink and expand multiple times at the same time and use linear guides as the carrier to make it run smoothly, without wear, and with good product repeatability.

- The double-head shrinking machine can adjust the distance between the two heads according to the length of the processed pipe.

- Single clamping or double clamping are available according to the length of the pipe.

- The steel tube shrinking machine has the characteristics of convenient operation, stable performance, high work efficiency, and high safety factor. It is an ideal piece of equipment for the processing industry.

Instructions for the Safe Operation of the Tube Shrinking Machine:

- When unloading the mold of the tube shrinking machine, the mold should be on the bottom to take out. When taking out the mold in the mold, one mold must be installed again. Four pieces cannot be taken out at the same time to avoid the inner mold of the tube shrinking machine from falling out.

- Semi-automatic tube shrinking machine, when the shrinking tube feeds, the person stands at the correct position and holds the tube material into the die with both hands. Do not use excessive force, and then push it evenly until it is in place to complete the removal of the tube material.

- In the normal operation of the automatic pipe shrinking equipment, the operator should always pay attention to the work of the stroke guide rail and add lubricating oil to the guide rail no less than 4-5 times in a normal working day to ensure the normal operation of the guide rail.

- The contractor must wear earplugs or earmuffs during work.

- After getting off work on the same day, you must organize the post and maintain the machine daily, and fill in the equipment maintenance form carefully. Turn off the power switch and auxiliary gas before leaving to get off work.

General Troubleshooting:

- There is no magnetism during the jogging movement?

Check from the magnetic line of the contactor to see if there is an open circuit, including the normally open contact of the contactor, the product line plug, and the stop button. And whether it is damaged, or whether the inserted relay has tripped.

- There is a buzzing sound in the contactor during work?

Open the bottom cover of the contactor and clean the oil or rust on the two sides of the iron core.

- When using automatic, the time breaker works overtime.

The time breaker is damaged.

- The fuse is burned out when starting up.

The line is energized or the motor is burned out.

- No response to startup?

If the circuit is short-circuited during startup or frequent power failure, check whether the auxiliary contact of the contactor and the product line plug is damaged and whether the button is stuck.

Pipe Shrinking Machine Manufacturer-YG Machinery

YG(YuGong) Machinery is a professional manufacturer, engaged in steel machines for over twenty years. We mainly supply road construction machines, steel processing machines, drilling machines, and others. We pursue manufacturing machines with high quality, great performance, and affordable prices. Besides the steel-size shrink machine, we also have an electric tube bender, mini concrete pump, mortar spraying machine, portable sand blasting machine, steel bar bending machine, I-Beam bending machine, rebar threading machine, stirrup bending machine, rebar upsetting machine, rebar derusting machine, steel straightening and cutting machine, rebar cutting machine, anchor drilling machine, etc. Welcome to contact us to get more details about the equipment you are interested in.